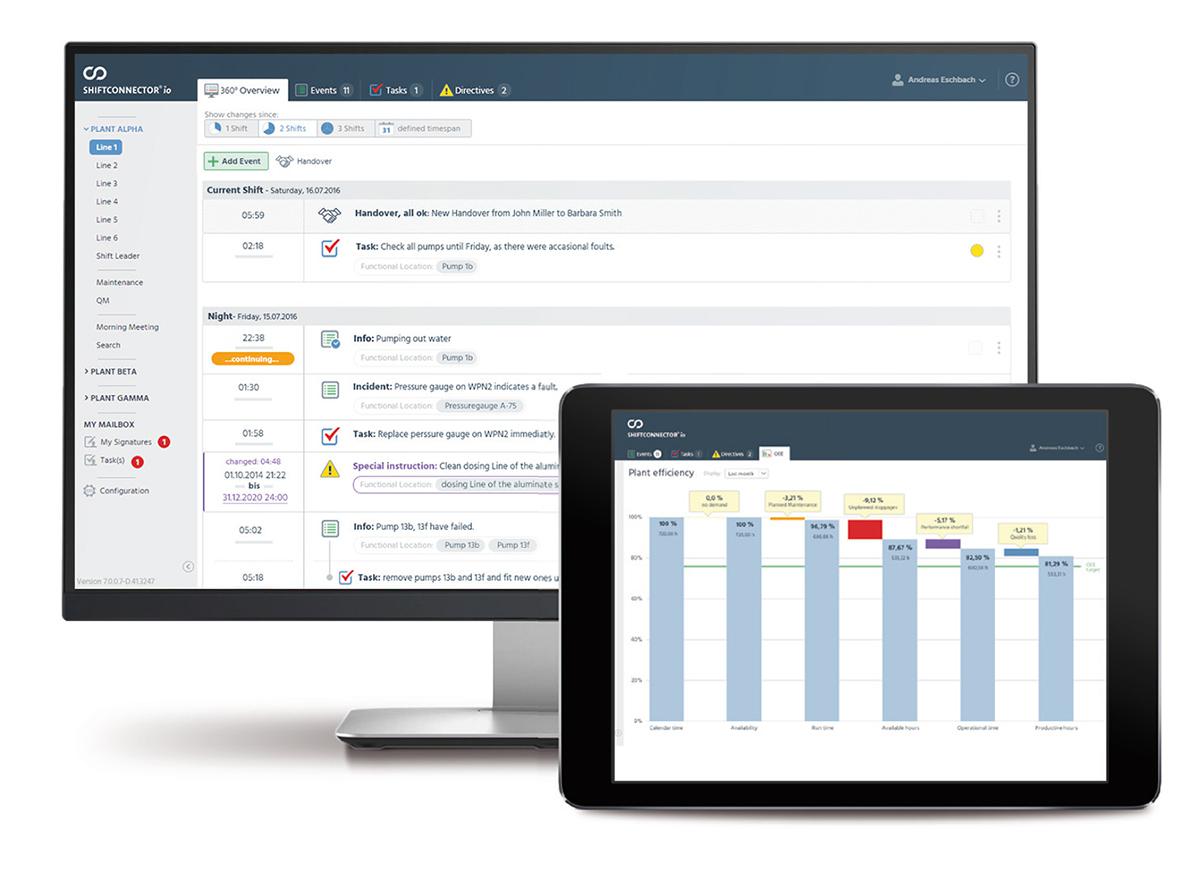

Shiftconnector® —Digital Transformation for Chemical Manufacturing

Find out why more global manufacturers are turning to Shiftconnector to track and manage important shift change information.

Connect Human Intelligence with Technology and Plant Data

One of the biggest opportunities for digital transformation happens at shift change because that is often where information transfer fails. Running a 24/7 production plant requires tight alignment between shifts to alert teams to problems, identify problems, and document changes.

When shift changes are managed through stand-up meetings or spreadsheets, information can be overlooked or forgotten. Equally problematic, the information may not be accessible or visible to all the right people.

Digitalization Solutions for Chemical Manufacturers

Shiftconnector helps chemical manufacturers digitally transform their operations to ensure safety and improve plant effectiveness. The award-winning solution is trusted worldwide by leading manufacturing companies such as Bayer, DuPont, BASF, and Albermarle.

Shiftconnector is a no-code, SaaS solution for plant process management (PPM) that easily integrates with other plant operation systems like SAP and Aveva PI.

Operate Smarter and Safer with Shiftconnector GO

Preparing Process Industries for Industry 5.0

Shiftconnector’s intuitive interface and workflow allow teams to make better-informed decisions, reducing cost and increasing productivity. With Shiftconnector, plant teams have anywhere/anytime access to real-time information—sensor data, IIoT equipment, field notes from operators and inspectors, etc. They can streamline operations, respond faster to changes, recover quickly from disruptions, and reimagine plant operations.

Smarter Plant

Optimize plant processes for higher productivity and product consistency.

Safer Plant

Reduce accidents and downtime.

Stronger Plant

Improve resilience and adaptability.

Röhm Digitalizes Processes With Shiftconnector

With the help of Shiftconnector, a software solution from the global software provider eschbach, chemical company Röhm has digitalized its processes and, in so doing, achieved lasting improvements in the areas of safety, quality, and productivity.

Here's What Our Customers Are Saying

"With Shiftconnector, we now have an instrument with which we can further increase quality, efficiency, and ultimately safety in our operations."

"Shiftconnector has significantly improved and facilitated our data collection. Important information is available across departments, so overall transparency could be increased."

"Shiftconnector provides a common framework for continuous improvement of Albemarle‘s manufacturing execution processes at our production sites worldwide. Shiftconnector helps increase operation discipline through a set of digital playbooks, best practices, and KPIs - including OEE - and is a key component of our journey to manufacturing excellence."