Shiftconnector® GO Mobile Rounds

Streamline inspections and stay connected on the go.

Mobile Operator Rounds in the Chemical Industry: Information

Driving safety, efficiency and continuous improvement for the chemical industry

Paper-based operator rounds in chemical plants lead to inefficiencies, documentation gaps and delayed issue resolution, increasing safety risks and compliance challenges. Shiftconnector® GO for the chemical industry transforms inspection rounds by connecting field operators with the control room in real time. Streamline inspections and improve plant safety and productivity with a powerful mobile platform built for chemical manufacturing.

Offline Functionality

Operators can log data and complete inspections even in areas with no network coverage, syncing automatically when reconnected.

Improve Plant Safety

Digitally document inspection rounds, capture anomalies with photos, and instantly share critical information, even in remote or signal-limited plant areas.

Real-Time Connectivity

Allows field operators to log inspection data, report issues, and complete checklists on the go. Data syncs seamlessly with Shiftconnector, ensuring visibility of the mobile operator rounds for plant managers and maintenance teams.

Faster Decision-making with Our Plant Management Software

Collaboration

Seamless coordination for safer, more efficient chemical plants.

Key Features

-

Digital Shift Handover

-

Task & Event Tracking

-

Centralized Knowledge Management

Visual KPIs

Monitor critical performance metrics in real time and collaborate across teams and tiers.

Key Features

-

Customizable KPI Dashboards

-

Tier Collaboration Boards

-

Automated Alerts & Notifications

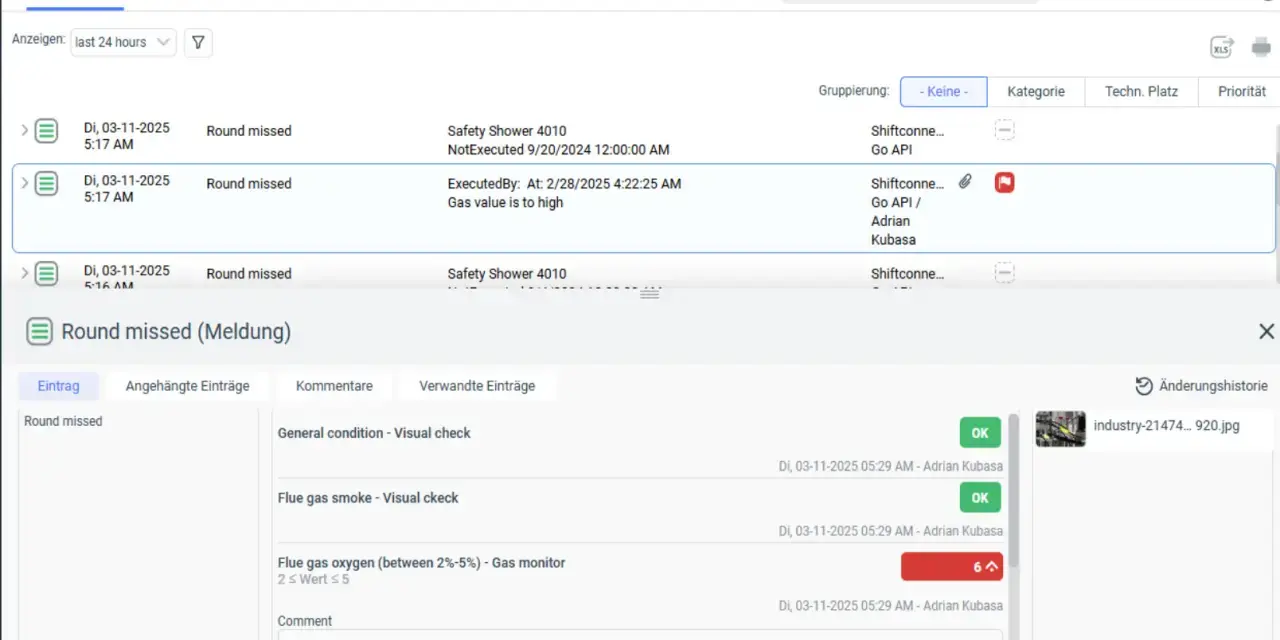

Shiftconnector GO

Digitize operator rounds for faster issue detection and improved plant safety.

Key Features

-

Mobile Inspection & Logging

-

QR Code Equipment Identification

-

Offline Functionality for Field Operators

Shiftconnector AI

Turn plant data into actionable insights with AI-powered search and recommendations.

Key Features

-

Smart Search for context-relevant results

-

AI-driven solution recommendations

-

Natural language queries

Performance Management – OEE

Optimize asset utilization with live OEE tracking and performance analytics.

Key Features

-

Real-Time OEE Monitoring

-

Automated Data Integration

-

Performance Trend Analysis

Shiftconnector GO

Digitize operator rounds for faster issue detection and improved plant safety.

Key Features

-

Mobile Inspection & Logging

-

QR Code Equipment Identification

-

Offline Functionality for Field Operators

What can Shiftconnector do for you?

The award-winning software is used by leading companies worldwide. For 20 years, Shiftconnector ® has improved communication between shift teams in the process industry.

Successful Cases of Software in Chemical Manufacturing

Hear what chemical manufacturing companies say about Shiftconnector and its impact on their production and operations.

Working with Our Chemical Production Software

Shiftconnector seamlessly integrates with existing plant systems, including MES, ERP, LIMS and SCADA, ensuring real-time data flow across operations for better visibility, efficiency and decision-making.

FAQ Chemical Manufacturing Software

How does Shiftconnector® GO for the chemical industry improve safety in chemical manufacturing?

Shiftconnector® GO enables field operators to digitally document inspection rounds, capture anomalies with photos, and instantly share critical information. This real-time visibility helps teams respond quickly to safety risks, reducing hazards and preventing potential incidents.

Does Shiftconnector® GO work with the Shiftconnector® platform?

Shiftconnector® GO is a mobile extension of Shiftconnector, allowing field operators to log inspection data, report issues, and complete checklists on the go. Data syncs seamlessly with Shiftconnector when a network is available, ensuring visibility of the mobile operator rounds for plant managers and maintenance teams.

Can operators use Shiftconnector® GO for the chemical industry in areas with no network connection?

Yes. Shiftconnector® GO works offline, allowing operators to record inspections and incidents in real time. Once reconnected, all data of mobile operator rounds for the chemical industry automatically syncs, ensuring no critical information is lost and making it an optimal solution for the chemical industry.

Resources & Downloads

Get the latest industry insights and updates with our latest blogs and whitepapers.

Whitepaper

Step into a New Dimension of Inspection Rounds - A Compass for Field Operators. Get a free download of the whitepaper.

Blog

Learn how real-time accountability improves team communication, safety, and decision-making in process industries.

Case Study

See how BASF uses digital tools to improve shift communication and keep production running smoothly.