HOW TO FUTURE PROOF YOUR CHEMICAL PLANT

Digitizing Communication at Your Plant Can Improve Safety and Efficiency

Are Your Information Management Systems Creating Risk?

Download this report to learn how your data and plant process management practices measure up to others in the chemical, pharma, and petro derivatives process industries. The team from 451 Research shares insights from 300 senior executives about how they are digitizing plant operations to increase safety, improve productivity, and minimize risk.

Get your copy of this special report to learn about:

- The advanced technology solutions your peers are using to digitize critical data in their chemical manufacturing plants

- The risks created by outdated information management systems, including communication breakdowns, errors, and safety lapses

- Why centralized data collection and storage is required to improve functionality and efficiency

- Key market trends and indicators you should pay attention to

Transforming Plant Operations

For nearly 20 years, eschbach has worked closely with global chemical manufacturers to develop software solutions for the process manufacturing industry. If the following information challenges are creating safety issues and limiting productivity at your plant, we can help:

- Outdated information management systems: You can't easily find or share important information stored in Excel spreadsheets, Lotus notes, or legacy software.

- Information silos: The right people may not have access to important information.

- Lack of prioritization and visibility: Information may be there, but if you don’t know to look for it, you don’t see it.

- Complexity and confusion: You don’t know what information applies to you and what to do about it.

- Limited reporting: You're unable to track and report on key performance metrics.

Download the Report

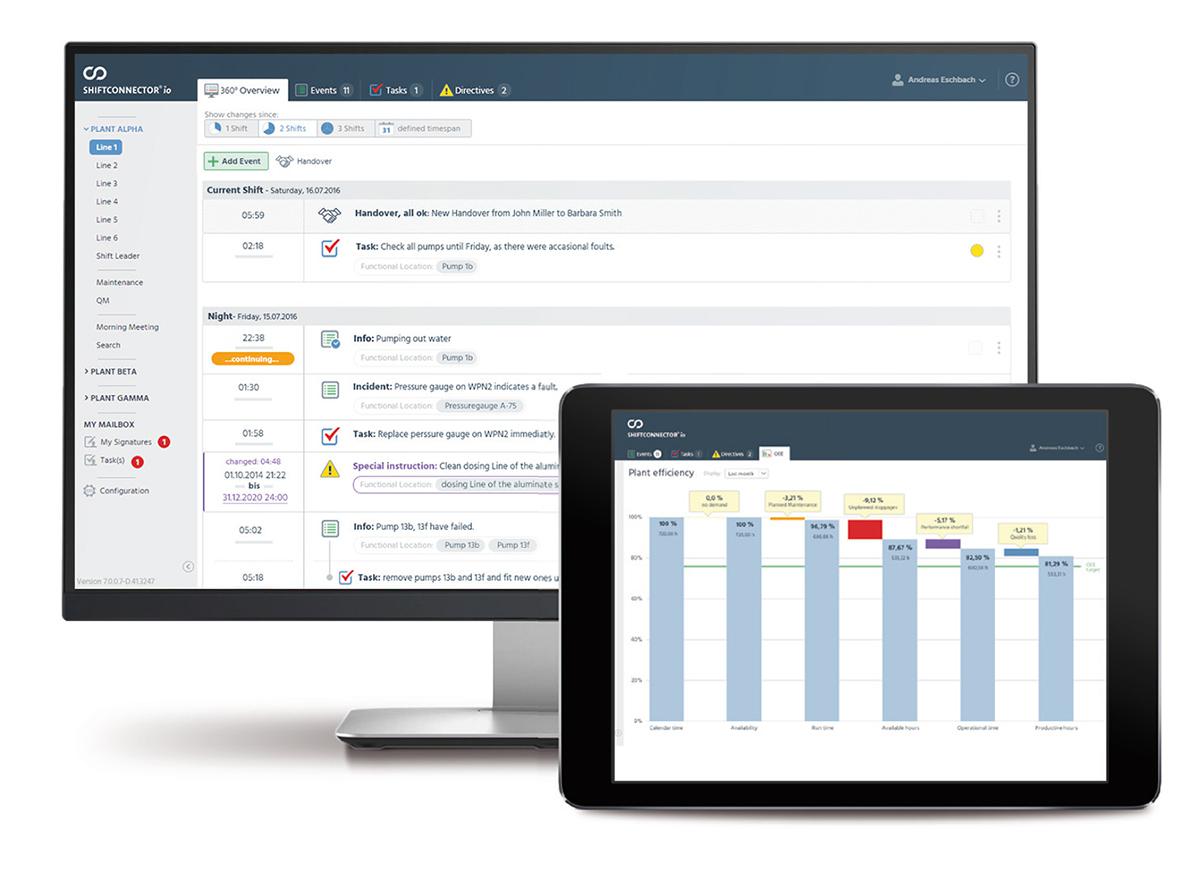

What is Shiftconnector®?

Shiftconnector is a no-code, SaaS solution for plant process management (PPM) that easily integrates with other plant operation systems like SAP and Aveva PI.

It helps chemical manufacturers digitally transform their operations to ensure safety and improve plant effectiveness. The award-winning Shiftconnector solution is trusted worldwide by leading manufacturing companies such as Bayer, DuPont, BASF, and Albermarle.

With Shiftconnector, you can transform your plant operations by:

- Giving everyone access to the right information at the right time to do their jobs well.

- Providing a real-time, 24/7 view into plant operations by connecting data from all systems, including automated sensors and IIoT devices.

- Centralizing data collection and storage to improve functionality and efficiency.

- Tracking and measure key performance indicators at the plant, site, and business unit levels.

- Creating a safe work environment by ensuring that critical data is available to the entire team.